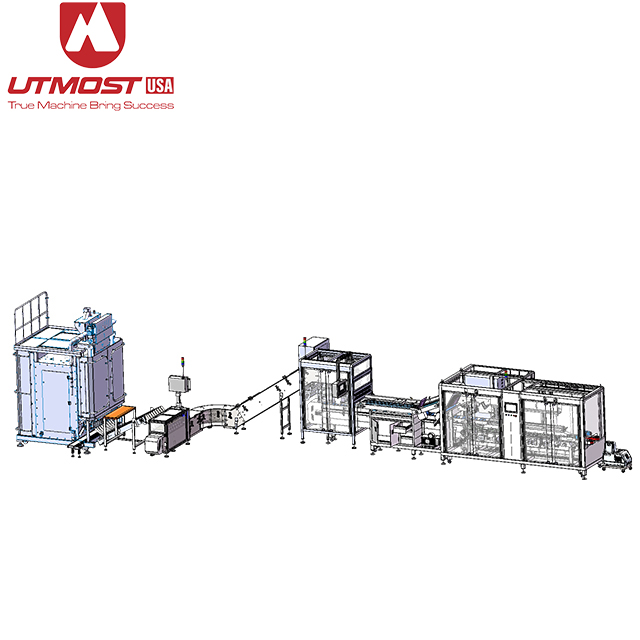

Multi-lane Stick Pack carton machine packaging solutions

Multi-lane Stick Pack Machine

Advantage:

Door opens → Machine stops

High-performance control system with multiple recipe storage

Supports various film rolls

Semi-automatic bag thickness adjustment

Self-diagnosing PID temperature control for precise heating

Automatic film correction system

Self-developed measuring system

Nitrogen filling system

Technical Parameters

| NO | Item | Parameters | |

| 1 | Model | UTGPH-8ST | |

| 2 | Packaging Type | Stick | Stick Pack |

| Weight | 10-20G | ||

| 3 | Speed | 40Strokes/min*8=320sticks/min | |

| 4 | Dosing System | Auger Filler±0.2g | |

| 5 | Power Supply | 3Phase AC220V 50-60HZ | |

| 6 | Power | About 22kw | |

| 7 | Air Consumption | 0.6Mpa, 1000NL/min | |

| 8 | Weight | About1800kg | |

| 9 | Overall Size | L2200 * W2150* H3680mm | |

Configurations

| No | Item | Brand |

| 1 | Touchscreen | Inovance |

| 2 | PLC | Inovance |

| 3 | Expansion Module | Inovance |

| 4 | Servo Drive (Horizontal Seal/Vertical Seal/Bag Cutting/Film Pulling) | Inovance |

| 5 | Color Mark Detection/Film Roll Joint Detection | SICK |

| 6 | Pressure Switch | SMC |

| 7 | Power Supply | Meanwell |

| 8 | Intermediate Relay | Omron |

| 9 | Solid State Relay | Schneider |

| 10 | AC Contactor | Schneider |

| 11 | Thermal Protector | Schneider |

| 12 | Circuit Breaker | Schneider |

| 13 | Temperature Control Module | Omron |

| 14 | Main Power Switch | Schneider |

| 15 | Servo Motor (Screw Control) | Inovance |

Servo Flexible Line

The servo flexible line is a continuous motion system driven by a high-speed servo motor. The line’s length and direction are customized according to the site layout, using chain plate conveyors and customized independent material trays. Each tray holds one small bag, and at the end of the line, a high-speed magnetic levitation linear motor switches mechanism ensures precise and fast delivery of small bags into the counting machine.

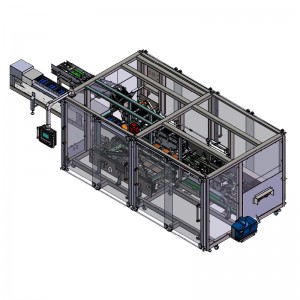

High-Speed Counting Machine

The GB-L60 box filling machine operates intermittently, suitable for larger-sized products. It features a motion control module that drives servo motors for accurate and stable operations. The machine has intelligent formulas and module guidance, with simple parameter settings. The machine’s structure is made of stainless steel, adapting to various product specifications and enabling quick specification changes.

Product Superiority

1.Intelligent operation: No product, no carton is fed out; no carton, no product is pushed.

2.It adopts multi – head rotary carton opening with an auxiliary carton – opening mechanism, featuring fast carton – opening speed and smooth shaping.

3.The whole machine is designed with flexibility. The servo system can quickly adjust the carton size, facilitating rapid model change.

4.It is equipped with a touch – screen and a graphical operation interface. Parameter settings can be stored, which is convenient for operation.

5.The main structure is made of SUS304 stainless steel and treated with a sand – blasting process. The overall appearance is beautiful. This process not only increases the hardness of the machine body but also improves the protection level.

Product Feature

1. Independent servo pusher for loading, max speed up to 60 cartons/min.

2. Revolutionary dual – head rotary carton – opening with pre – opening mechanism, ensuring smooth carton – forming, reliable and efficient operation.

3. Servo – driven control for stable and reliable machine performance, fast product changeover.

4. No carton opening without products, no material pushing without cartons.

5. Low – level alarm, 1.5m carton gate conveyor, can hold over 600 cartons at once.

6. 10 – inch HMI touch – screen, PLC motion controller, cantilever one – key operation adjustment panel.

7. Cartons conveyed out by clamping belts.

8. 10mm PC glass safety guard with interlock control.

9. Sealed by hot – melt spray glue.

10. Fitted with universal casters for quick machine movement and positioning.

Technical Parameters

| Device Speed | 50-60 cartons/min |

| Carton Specifications | L(140-260mm)*W(60-165mm)*H(30-125mm) |

| Power | 380VAC 50HZ |

| Air Pressure | 0.6m³/min |

| Overall Dimensions(Subject to Actual Situation) | L6118mm*W1750mm*H2000mm |

| Weight | 3000KG |

Major Dispositions

| Component | Standard Configuration | |

| Cartoner Drive | Main Drive | Siemens Servo Drive |

| Planetary Reducer | German NEUGART / Japanese SHIMPO | |

| Motor | SEW | |

| Mechanical Components | Module | SMOOTH |

| Pusher Guide Rail | THK/HWIN | |

| Mechanical Parts | MISUMI | |

| Bearing | Bearing THK/SKF/INA | |

| Cylinder & Solenoid Valve | SMC | |

| Vacuum System | Vacuum Generator | SMC/AIRBEST |

| Main Structure | Material | SUS304 Stainless Steel (Sandblasted) |

| Low-voltage Electrical | Low-voltage Electrical | Schneider / Omron |

| Photoelectric Sensor | Omron/SICK | |

| Control System | HMI Intelligent Touch Screen Control System | Siemens |